Railway companies are struggling to meet the growing industry needs for maintenance, technical service, and expansion. Regulations, design limitations, and material options limit the industry. AddPark designs system, sub-system, and component designs for railway systems according to additive manufacturing, and, if desired, completes certification processes and assumes the role of supplier.

Get Information

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc et massa ex. Morbi vitae lobortis odio.

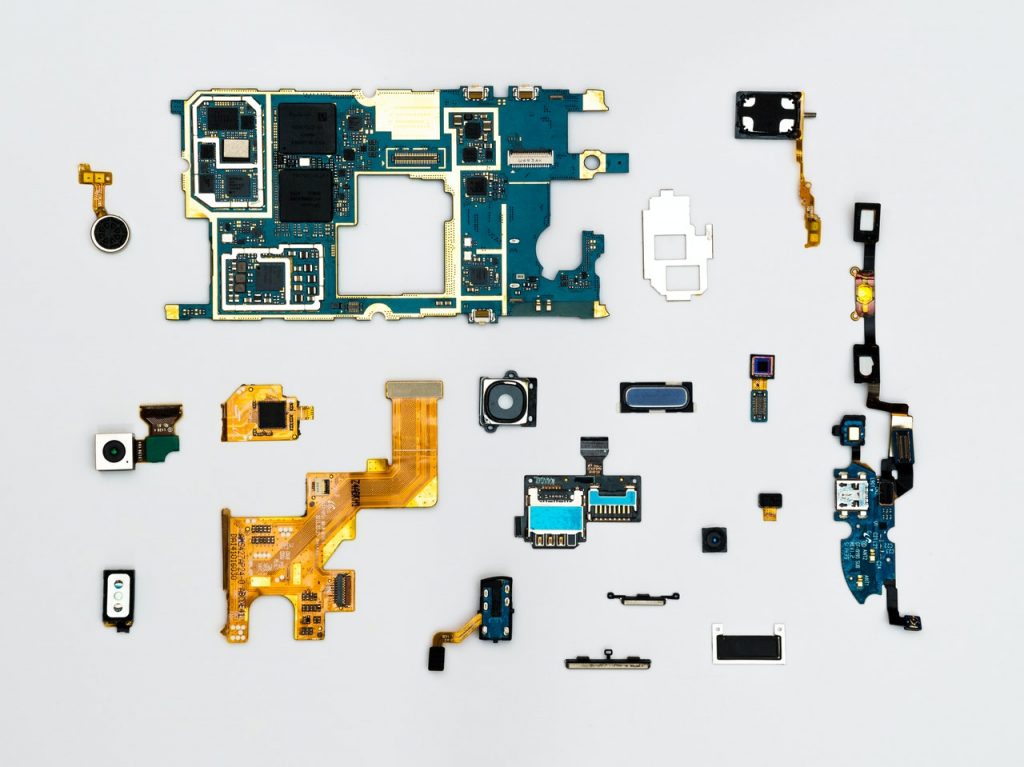

AM is a process of creating three-dimensional objects by adding layers of material according to a digital design. This technology has the potential to democratize the railway industry by enabling the production of customized parts and components at a lower cost and with shorter lead times.

In the railway industry, AM has been used to manufacture a wide range of parts, including structural components, mechanical parts, and electrical components. For example, Bombardier has been using 3D printing to produce prototype parts and small batch production of plastic and metal parts, such as cable ties and brackets. Siemens has also been using 3D printing to produce spare parts, such as gears and bearings, which can be difficult to obtain in a timely manner. In addition, the Swiss Federal Railways have been using 3D printing to produce customized parts and tools, such as jigs and fixtures, as well as production parts, such as mounting brackets and couplers.

In conclusion, AM has the potential to democratize the railway industry by enabling the production of customized parts and components at a lower cost and with shorter lead times. As the technology continues to advance, it is likely that we will see even more applications of 3D printing in this sector. Is there anything else I can help with?