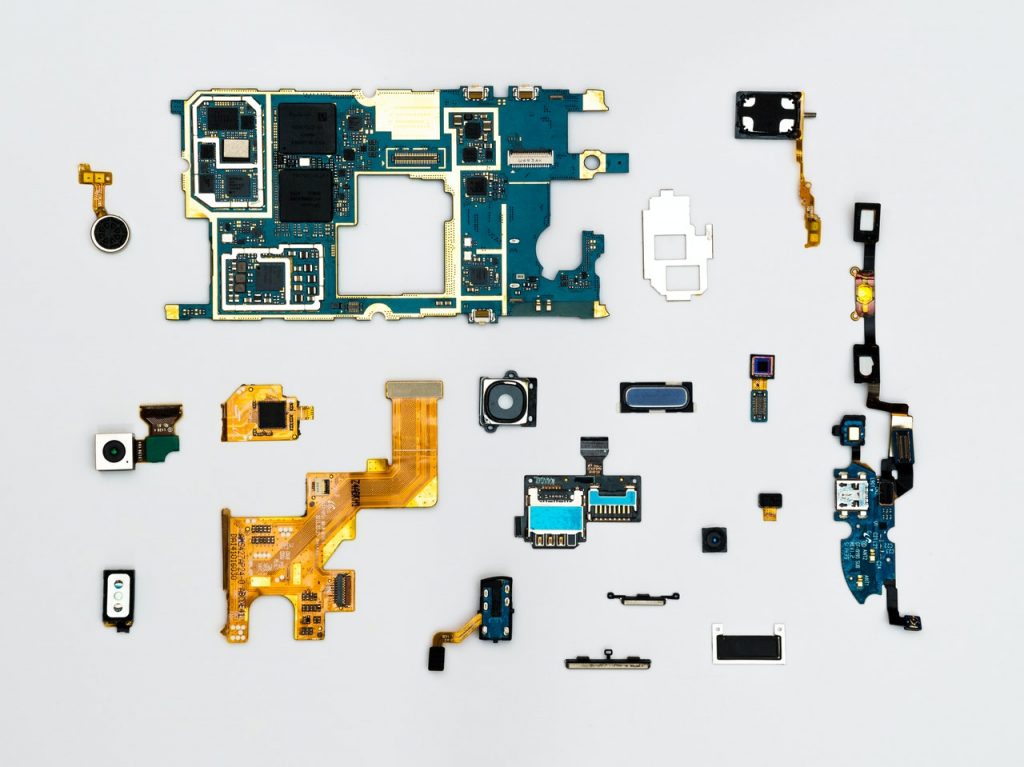

Manufacturing and maintenance departments are agile departments that produce a wide range of different product groups using a wide range of technologies. 3D printers simplify our daily lives by producing solutions such as parts with supply shortages, demand-oriented designs, assembly guides, low-volume injection molds, tools and equipment. We design and produce special products that the manufacturing and maintenance departments need on demand.

Get Information

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc et massa ex. Morbi vitae lobortis odio.

AM is a process of creating three-dimensional objects by adding layers of material according to a digital design. This technology has the potential to revolutionize the way products are manufactured and maintained. In manufacturing, AM can be used to produce complex parts and prototypes quickly and cost-effectively.

In maintenance, AM can be used to produce spare parts on demand, reducing the need for large inventory and minimizing downtime. For example, a mining company can use 3D printing to produce spare parts for heavy machinery on site, reducing the need to wait for parts to be shipped from the manufacturer. In the military, 3D printing has been used to produce spare parts for equipment in the field, such as gears and bearings, which can be difficult to obtain in a timely manner.

Overall, AM has the potential to revolutionize the way products are manufactured and maintained, reducing costs and improving efficiency. As the technology continues to advance, it is likely that we will see even more applications of 3D printing in these areas. Is there anything else I can help with?