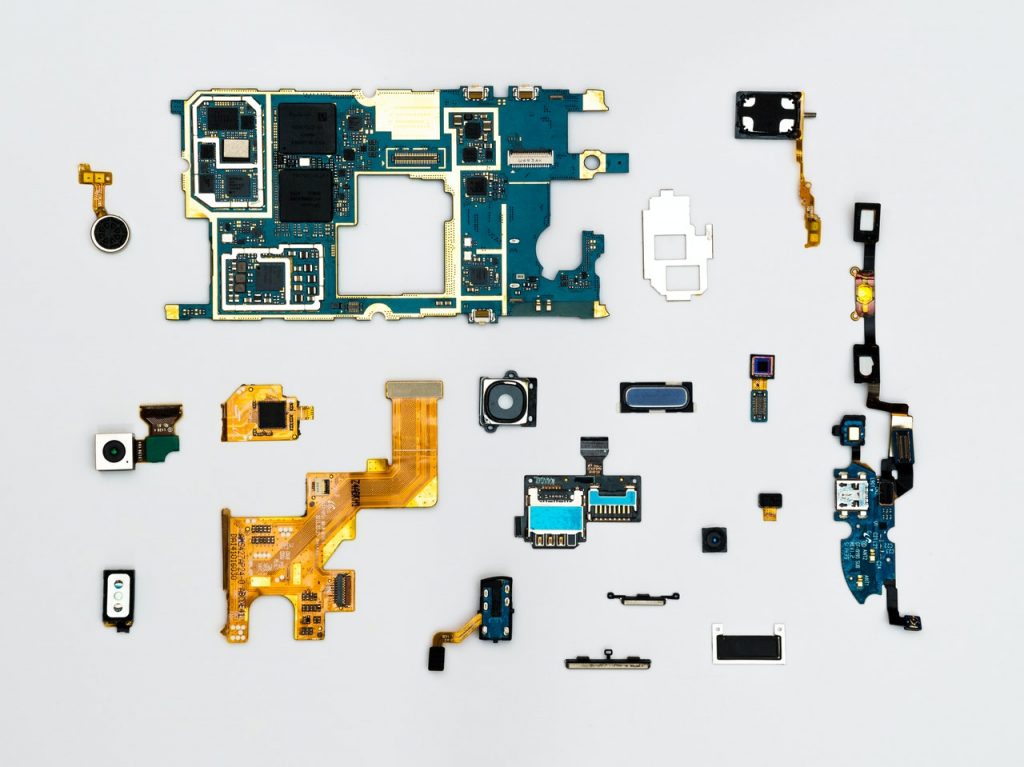

Additive manufacturing has become a game-changer in industries such as aviation, defense, and aerospace, allowing for the creation of complex, customized parts and systems with unprecedented speed and efficiency. These industries have specific requirements for the materials used in their products, and often require parts with high strength, low weight, and the ability to withstand extreme temperatures and harsh environments. Common materials used in these industries include metals such as titanium, aluminum, and steel, as well as advanced polymers such as PEEK, PEKK, and Carbon PEEK.

Get Information

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc et massa ex. Morbi vitae lobortis odio.

At AddPark, we have extensive expertise and knowledge in these areas, and are constantly seeking out new ways to push the boundaries of what is possible with additive manufacturing.

Additive manufacturing allows for the production of parts with complex geometries and intricate internal structures that are not possible with traditional manufacturing methods. This enables the production of lightweight, high-strength parts that can meet the demanding requirements of these industries. Additive manufacturing also allows for the production of small batch sizes and custom parts on-demand, making it an ideal solution for prototyping and low-volume production.

The size limitations of additively manufactured parts are dependent on the specific technology being used. In general, the size of parts that can be produced with additive manufacturing is limited by the size of the build envelope of the printer, which can vary significantly depending on the specific machine being used. However, some additive manufacturing technologies, such as large-scale 3D printing, are capable of producing parts with much larger dimensions.

Additive manufacturing has been used to produce a wide range of parts and systems in the aviation, defense, and aerospace industries, including structural components, engine parts, and satellite components. Some examples of successful industrial case studies in these industries include the production of fuel nozzles for aircraft engines using metal additive manufacturing, and the use of additive manufacturing to produce complex, lightweight satellite structures.

At AddPark, we have a wealth of experience working with industry leaders in the aviation, defense, and aerospace sectors, and are committed to supporting our customers in their efforts to leverage the full potential of additive manufacturing. From product design and prototyping to process development and certification, we have the expertise and resources to help our customers succeed in these dynamic and challenging markets.