Additive manufacturing, or 3D printing, has the potential to revolutionize the automotive industry by providing new design freedoms, enabling the production of customized and low-volume parts, and reducing material waste. At AddPark, we utilize our advanced technological infrastructure and expertise in additive manufacturing to develop innovative solutions for the automotive industry.

Get Information

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc et massa ex. Morbi vitae lobortis odio.

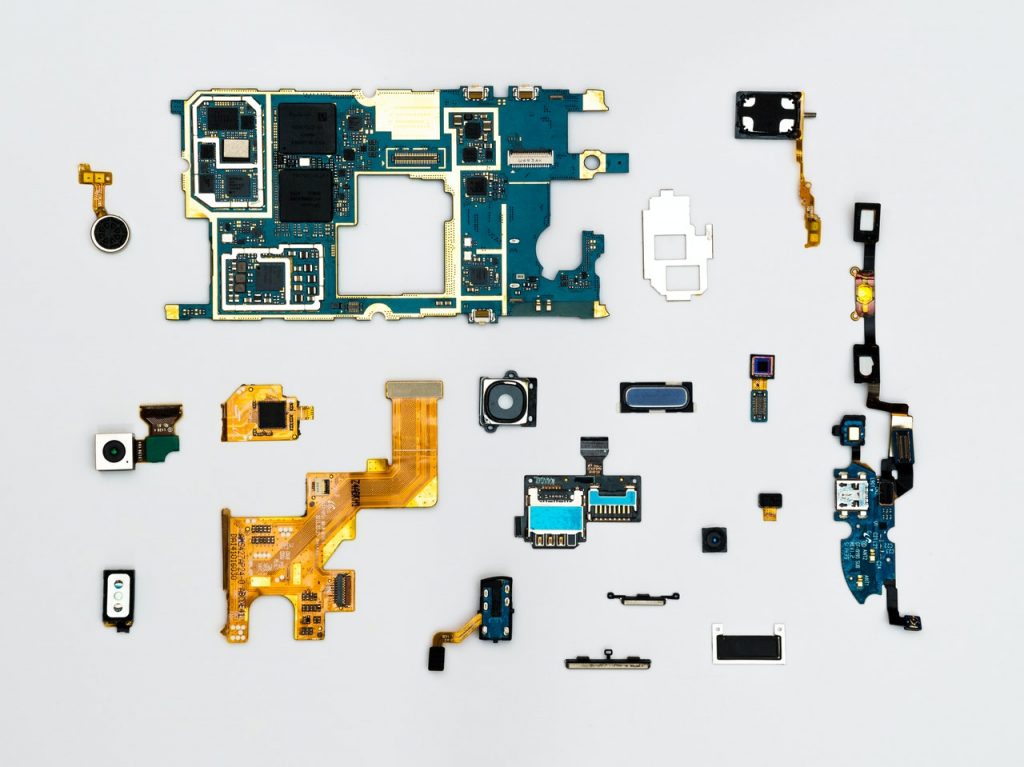

One of the main advantages of additive manufacturing in the automotive industry is the ability to produce complex geometries and internal features that would be impossible to produce using traditional manufacturing methods. This enables the design and production of lighter, stronger, and more efficient parts, which can improve the overall performance and fuel efficiency of vehicles.

Additive manufacturing can also be used to produce low-volume or customized parts, such as spare parts or aftermarket accessories. This can reduce inventory costs and lead times, while also increasing customer satisfaction.

Some of the specific applications of additive manufacturing in the automotive industry include the production of engine parts, drivetrain components, and structural elements. It is also being used to produce tools and fixtures for manufacturing, as well as end-use parts for prototyping and functional testing.

One key area where additive manufacturing can add value to the automotive industry is in the production of customized and low-volume parts. Traditional manufacturing processes often require large minimum order quantities and do not allow for customization, but additive manufacturing allows for the production of unique and customized parts on demand. This can be particularly useful for spare parts and aftermarket components, as well as for prototyping and testing new designs.

In addition to customizability, additive manufacturing can also reduce material waste in the automotive industry. Traditional manufacturing processes often generate a significant amount of scrap material, but additive manufacturing can produce parts with minimal waste and near-net shape, resulting in cost and resource savings.

One of the main ways we do this is by helping companies to design and prototype parts using advanced materials and techniques. Our team of experts is skilled in using design software and tools to create parts that are optimized for additive manufacturing, and we can work with you to develop prototypes that meet your specific requirements.

In addition to prototyping, we also have the capability to produce small batches of parts using additive manufacturing, which is ideal for companies that need to test and validate designs before moving to mass production. This allows our customers to make quick and informed decisions about the feasibility and cost-effectiveness of their parts.

Overall, AddPark is committed to working with the automotive industry to leverage the benefits of additive manufacturing and drive innovation and efficiency. Our team has a wealth of experience and know-how in the field, and we are dedicated to supporting companies in the automotive industry as they explore the possibilities of additive manufacturing.