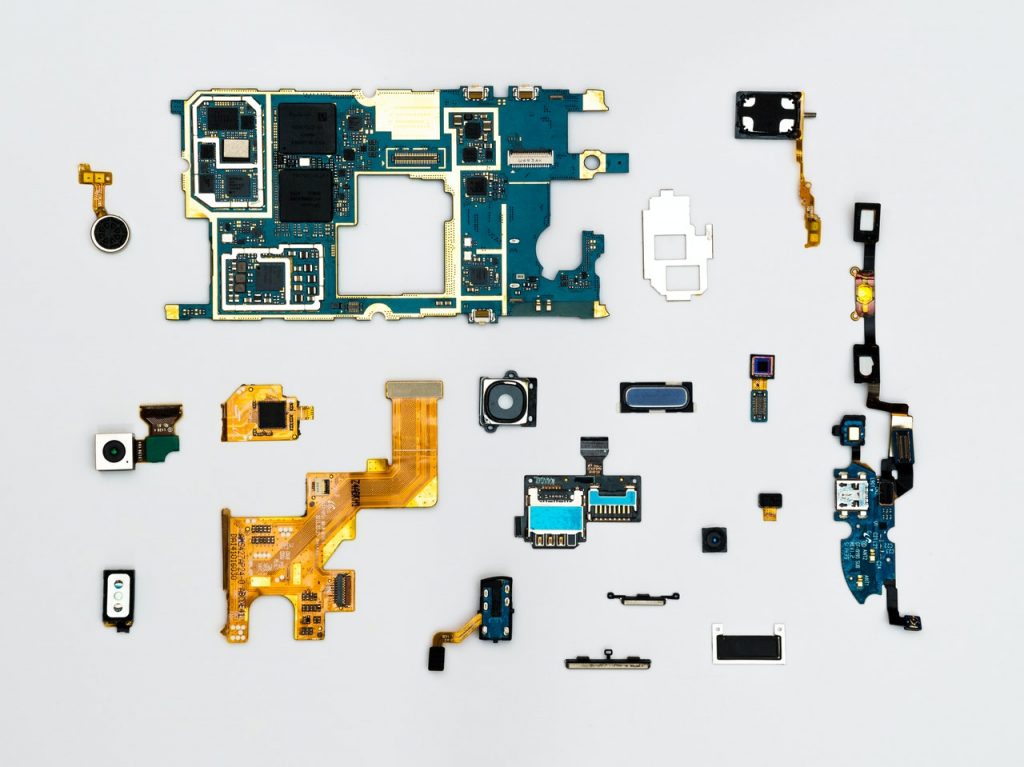

The use of additive manufacturing in the power and energy sector has gained significant traction in recent years, due to the ability to quickly produce complex and customized components. Additive manufacturing allows for the creation of parts that would be impossible or impractical to manufacture using traditional methods, such as casting or machining.

Get Information

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nunc et massa ex. Morbi vitae lobortis odio.

One example of how additive manufacturing can be used in the power and energy sector is the production of heat exchangers. These components are used to transfer heat between fluids, and are critical in the operation of power plants and other energy production facilities. Additive manufacturing allows for the production of heat exchangers with complex internal geometries and precise dimensional tolerances, improving efficiency and performance.

Another application of additive manufacturing in the power and energy sector is the production of electrical components, such as connectors and busbars. These components can be quickly and accurately produced using additive manufacturing, reducing lead times and improving the reliability and performance of electrical systems.

AddPark has significant expertise in the use of additive manufacturing in the power and energy sector, and can bring added value through its design capabilities. By leveraging the design freedom offered by additive manufacturing, AddPark can help facilities optimize the performance and efficiency of their components and systems. The use of digital inventory systems can also help facilities manage their production, reducing waste and improving efficiency.